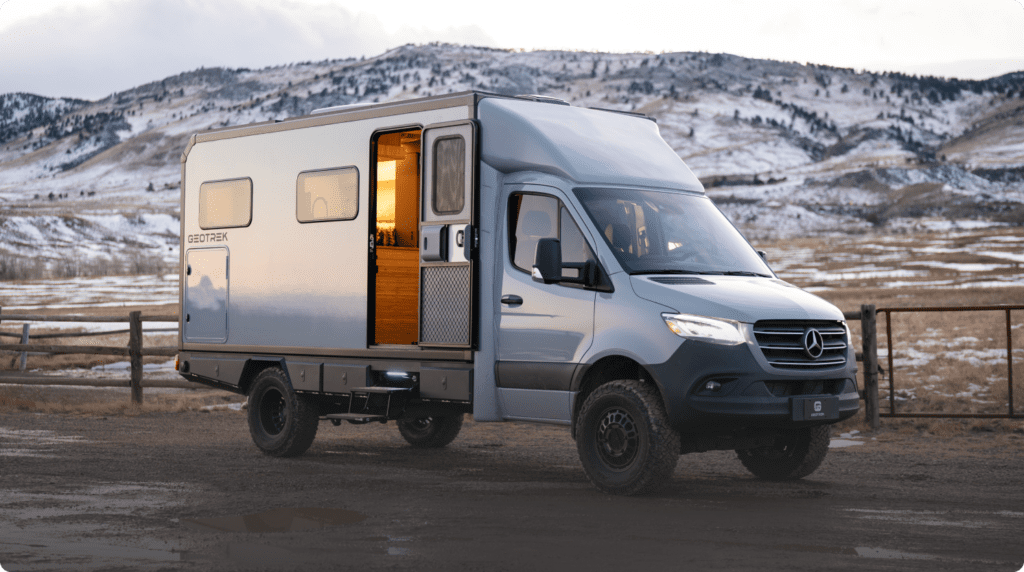

When most people think about buying a camper van, they imagine walking into a showroom, choosing a model, and driving away. What they don’t see is the precision, craftsmanship, and innovation that happens behind the scenes to build a van that can handle real adventure.

At Geotrek Vans, we build differently. And we think you should know exactly how.

Built in Colorado, Tested in Extreme Conditions

Our facility in Colorado isn’t just where we assemble vans — it’s where we innovate, test, and refine every single detail. After New Year’s 2025, our co-founders Mark and Grant drove one of our vans to the Arctic Circle and back. Not for fun (though it probably was), but to cold-weather test our systems in the harshest conditions possible.

What came out of that trip? An entirely new insulated floor design, CNC-cut to fit perfectly between the ridges of a Sprinter van, maximizing thermal efficiency without sacrificing space.

That’s how we work. Real-world testing leads to real improvements.

The Showroom Experience: Touch, Feel, Compare

Before you commit to a build, you need to actually experience what van life feels like. Our G Patio houses multiple fully-built vans where you can climb in, test the layout, open cabinets, and see how different configurations work for different lifestyles.

Inside our sales office, you’ll work with our team to dial in exactly what you need — not what we want to sell you. We have fabric samples, cabinetry colors, wheel and tire upgrade options, and ski boxes on display so you can make informed decisions about your build.

Our sales team doesn’t just sell vans. They learn how you’re going to use your van, where you’re going, and what matters most to you. That’s how we perfect a build that’s right for your life.

Custom Cabinetry: The Geotrek Difference

Walk into most production van facilities and you’ll find MDF or particle board cabinets. Walk into ours and you’ll find solid bamboo cabinetry that we manufacture ourselves.

We own two CNC machines — one smaller format and one large enough to cut full-length ceilings for a Sprinter 170 or complete wall panels. This gives us two advantages most builders don’t have: precision and flexibility.

Every cabinet piece is cut, assembled, sanded, and finished in-house. Our team hand-applies Osmo oil or tung oil, rounds every edge where fingers might go, and ensures each piece cures properly before installation. The quality difference is immediately obvious when you open a Geotrek cabinet door.

But the real advantage of owning our CNC machines? We can innovate fast. When we identify an improvement, we make the change immediately — no waiting on a third-party supplier.

Manufacturing Efficiency: The Anti-Spaghetti Method

In manufacturing, there’s something called a “spaghetti chart” — you track a builder’s movements throughout the day, and if they’re inefficient, the path looks like a tangled mess.

We eliminate that with strategic pre-staging. Every van that enters a build bay has a cart behind it loaded with everything that builder needs: every screw, every nut, every washer, every cabinet, the refrigerator, the mattress. Our pre-production specialist Aaron sets up the next six vans, pre-wiring outdoor showers, hot water heaters, and electrical systems so they’re ready to install the moment a van reaches the build bay. No unnecessary walking. No hunting for parts. Just efficient, high-quality work.

Phase One: Where the Magic Starts

Before a van becomes the adventure vehicle you see on Instagram, it goes through Phase One. This is where we cut holes for windows and fans, install insulation, lay floors, and run all the wiring that makes your electrical system work.

One of our favorite moments is when customers come to pick up their finished van and we show them Phase One photos. Seeing the “arteries” of your system — where every wire runs, how the insulation is applied, what the lizard skin coating looks like — gives you confidence in what you’re buying.

Speaking of lizard skin: this truck bed liner-style coating gets sprayed on the interior walls of your van before insulation goes in. When the sun hits the outside of your van, lizard skin makes it extremely difficult for that heat to penetrate through, keeping your interior significantly cooler in summer heat.

Quality Control at Every Step

From Phase One through final build, multiple quality control inspections happen along the way. We don’t wait until the end to catch mistakes — we catch them early, fix them immediately, and ensure your van leaves our facility exactly as it should be.

Our inventory is strategically placed throughout the facility near the areas that need it most. This isn’t just about convenience — it’s about making sure that when a van enters a build bay, we have everything we need to complete it without delays.

Service and Customization After Purchase

Your relationship with Geotrek doesn’t end when you drive away. Our service department handles everything from routine maintenance to adding features you didn’t include in your original build.

Want to add a heater, ski box, air conditioner, outdoor shower, or water heater after the fact? Our service team can install it. Realized you need something different after a few months on the road? We’ll make it happen.

The People Behind Your Build

What this article can’t fully capture is the team. The cabinet assemblers who hand-finish every piece. The Phase One specialists who ensure your insulation is perfect. The build bay technicians who install your electrical system with precision. The operations leads who keep everything running smoothly.

And Mark and Grant, our co-founders, who are still here every day, still innovating, still testing vans in extreme conditions to make sure what we build actually works in the real world.

Come See It Yourself

Reading about our process is one thing. Seeing it in person is something else entirely. We welcome customers to tour our facility, meet the team, and even see the builder who’s working on your specific van.

You’ll leave with confidence that your Geotrek van isn’t just assembled — it’s engineered, tested, and built by people who actually care about what they’re creating.

Because when you’re 200 miles from the nearest town and your van needs to perform, the details matter. And details are what we do best.

Ready to start your build? Visit us in Colorado or reach out to our sales team to learn more about our current models and customization options.